ENGIE Services US (ENGIE) is a national energy infrastructure and building services company that helps education, government, commercial, and industrial customers become more efficient, productive, and sustainable. ENGIE oversees a number of energy related services – from grid-scale solar farms and community solar gardens (CSG) to battery-based energy storage and is responsible for supplying energy to nearly 50% of Fortune 100 companies.

Jamal Aboueljoud, the Director of Post-Construction Services for ENGIE’s California branch, leads a team of about 10 O&M technicians. Seeking to address several know process inefficiencies tied to field processes, the ENGIE team implemented the Scoop platform to automate report generation, improve data collection and access in the field, and enable better communications for asset management.

Key Results

- $179,000 in total annualized operations savings

- $17,900 in total annualized savings per employee

- $30,000 annualized savings from repeat field trips needed by busy field personnel

“Scoop has helped us tremendously with organizing our work, not to mention being a major asset for my team in the field… We are looking forward to continuing our fruitful relationship with Scoop for years to come.”

Jamal Aboueljoud, Director, Post-Construction Services

Operational Challenges

With an estimated peak load totaling nearly 13,000 MW, in addition to providing electricity services to residential and small businesses in 12 US states, ENGIE has become one of the world’s major solar energy suppliers.

Traditional post-construction maintenance and production site technicians rely on straightforward processes and checklists to aid in identifying discrepancies and reporting on them. Because ENGIE operates and supports thousands of individual work sites across the US, obtaining and reporting on the right information is crucial to the success and future of the company.

Jamal Aboueljoud, the Director of Post-Construction Services for ENGIE’s California branch, leads a team of about 10 O&M technicians who are considered the lifeblood that keeps the company branch going. “We maintain the [site system] so that it is operating and producing the energy that is guaranteed…making my department a critical part in maintaining the system properly,” said Aboueljoud.

Inefficient Report Generation

The primary issue that Aboueljoud and his crew faced was a lack of efficiency in their report generation process. “It literally took us months to capture the right information and to go back and decipher it (into a report),” he says. For Aboueljoud and his crew, taking weeks to generate reports for nearly 550 sites annually meant they had to manually organize their data assets from a single folder in order to reflect the correct project site, which took a substantial amount of time to complete.

Related: Solar CRM Software: The Easy Way to Organize Your Data & Processes

“It was not fun,” said Erica Sutton, who leads Operations and Accounts, and was responsible for manually compiling every report by hand. “Before Scoop, I had to manually open a folder of approximately one hundred pictures and manually zoom in to get the inverter model number and locate the correct array for each model number.” According to Sutton, reports that summarized on an average of six sites typically took upwards of a week to complete, with smaller reports taking several hours to finish.

“Before Scoop, I had to manually open a folder of approximately 100 pictures and manually zoom in to get the inverter model number…”

Erica Sutton, Operations and Accounts Lead

Lack of On-Site Procedures Causing Rework

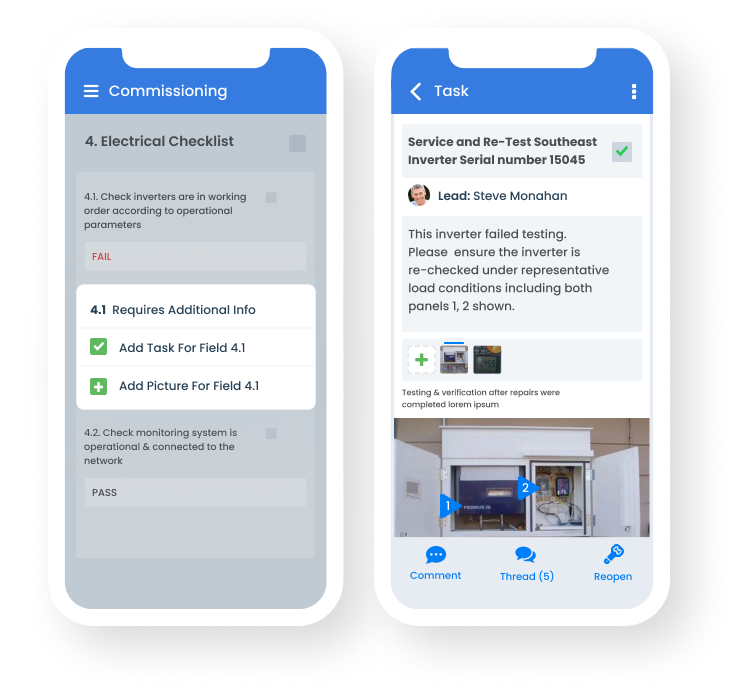

A major challenge for field technicians was the lack of structured step-by-step procedures when visiting a site. “Unless you were extremely good at keeping track of all the action items that are needed to be done at each site, it would be difficult to gather all the right information for a complete report,” said Ric Solario, Lead PV Field Engineer.

The lack of a streamlined procedure occasionally meant having a lot missing information, which greatly increased the number repeat site visits—disrupting daily schedules and wasting money on jobs which should have been done right the first time. On average, repeat site visits cost Ric and his team between $300-500 per trip, and according to Aboueljoud, occurred 70% of the time.

Related: The Solar Site Survey App That Improves Compliance

Gaps in Asset Management

The lack of an asset management system impacted both field and office crews. For Aboueljoud’s crew, organizing site assets and data—whether images, documents, or comments—was imperative for clear communication between field and office teams. Using traditional texts and email messaging for communication meant it was easy for information to fall through the cracks, especially when communicating with multiple team members simultaneously. Missing information meant an increase in repeat site visits, which further led to wasted time and resources.

“Unless you were extremely good at keeping track of all the action items that are needed to be done at each site…it would be difficult to gather all the right information for a complete report.”

Ric Solario, Lead PV Field Engineer

The Solution: Scoop Solar

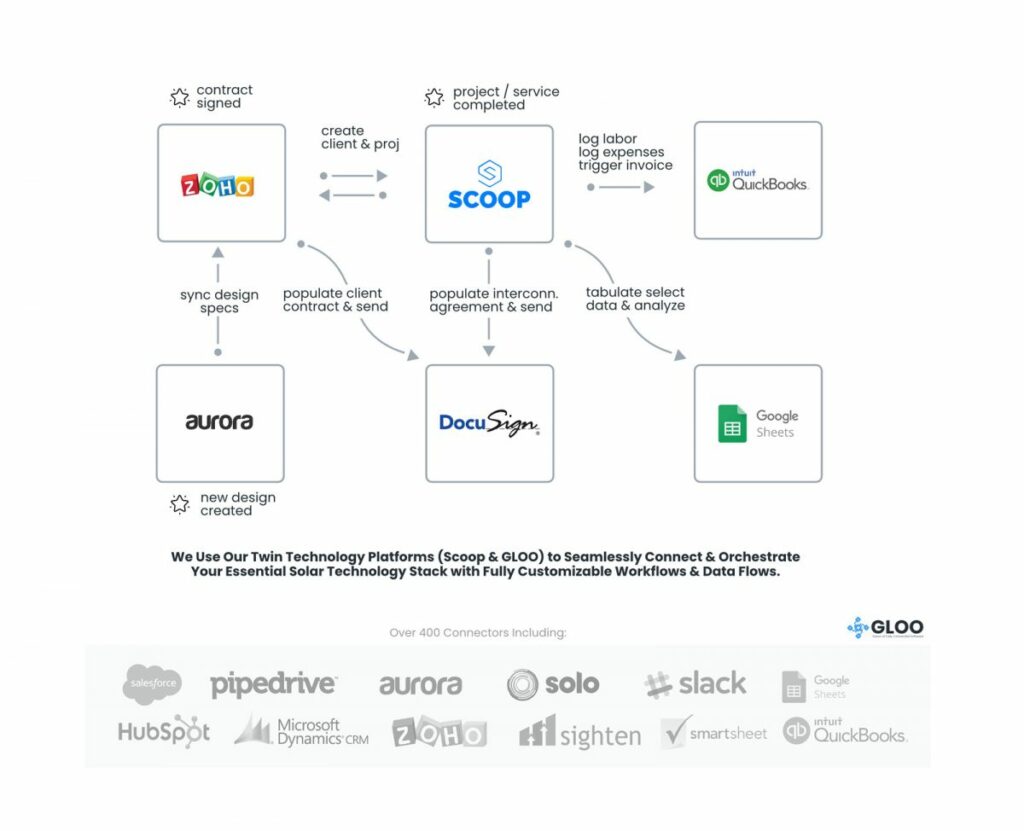

ENGIE began working with Scoop Solar through the Easy Launch Package (ELP), which included a professional setup of the Scoop app, 3 WorkApp™ templates based on ENGIE’s solar processes, admin and user training, and bi-weekly consultation sessions for 3 months.

Aboueljoud and his crew took an immediate liking to the software and saw its potential to resolve the challenges they were facing. Leveraging the Scoop platform, the ENGIE team began implementing several changes to their operations, resulting in a more efficient method to manage both solar and battery storage services.

Automated Report Generation

Using Scoop’s configurable report templates to automatically compile field data and photos, report generation became a breeze with more accurate outputs in a fraction of the time. Erica could now complete multi-site reports in 1-2 days, with smaller reports taking as little as 5-10 minutes to complete. “Reporting has never been easier,” she says. “With our crews on the field feeding me all the right information, it takes literally minutes to create a report compared to the hours I used to spend on finding and fixing the data we received before Scoop.”

Improved Data Collection and Access in the Field

Ric supplied his team with mobile-based digital check-lists and mandatory fields to be completed before finishing a site inspection, so that field workers could now focus their attention on new site inspections, and avoid repeat visits. Procedures were completed with greater accuracy, with zero repeat truck rolls and more accurate data for reporting. “Scoop has made site inspections as straight-forward as it can be. Now we can prevent all our field technicians from making the small mistakes that can lead to big costs and a lot of wasted time” said Ric.

Connected Asset Management

The team began leveraging Scoop’s data management and communication capabilities to close the loop between field and office in an easy and straightforward way. Having the ability to share comments, images, and documents along with creating notifications makes it easy for Aboueljoud’s crew to stay on track for all their solar processes.

“Reporting has never been easier. With our crews in the field feeding me all the right information, it takes literally minutes to create a report compared to the hours I used to spend.”

Erica Sutton, Operations and Accounts Lead

The Result

Since implementing Scoop, Aboueljoud and his crew have seen an increase in efficiency across their entire department. Admin users now complete reports in a fraction of the time they used to by directly generating reports from the Scoop App. By attaching markups and comments to images and sharing them across the department, communication and asset tracking has never been easier.

The team is more productive both on site and in the office, and with the time saved from handling reports manually or repeating site visits, ENGIE can now focus 100% on growth.

For Aboueljoud, the solution has ancillary benefits that have helped him manage his crew more easily. With Scoop, he can run charts, reports and track how each member of his crew is performing based on form completions and comments—making it easy for him to deal with discrepancies, delays, and issues in a flash. With Scoop’s WorkApps™ he ensures processes consistency, accuracy, and efficiency year after year. Not only that, but Aboueljoud’s has even created several of his own custom WorkApps™ for team management.

There has been a dramatic reduction in the amount of missing and inaccurate data. Using Scoop’s digital checklists, site technicians are now able to follow easy, step-by-step procedures that promote best-practices when recording and generating site data. With complete and accurate form submissions, there’s rarely a need to return to the same site months later, saving ENGIE around $250 dollars per site visit in lost time. By using Scoop, ENGIE has achieved an estimated savings of upwards of $179,000 in annualized savings.

Specific savings have come from:

- $87,750 saved by reducing the effort associated with completing and submitting forms

- $30,000 saved by reducing repeat field travel for high value personnel

- $41,000 saved by eliminating manual data entry, updating, and dissemination of documents

- $18,400 saved through more efficient field issue reporting and sharing

- $2,000 increased uptime by identifying, communicating, and fixing issues faster

Looking ahead, the ENGIE team is confident they can scale their operations efficiently to respond to expected growth in the market. “Scoop has helped us tremendously with organizing our work, not to mention being a major asset for my team in the field,” Aboueljoud says. “I think I speak for everyone when I say that we are looking forward to continuing our fruitful relationship with Scoop for years to come.”